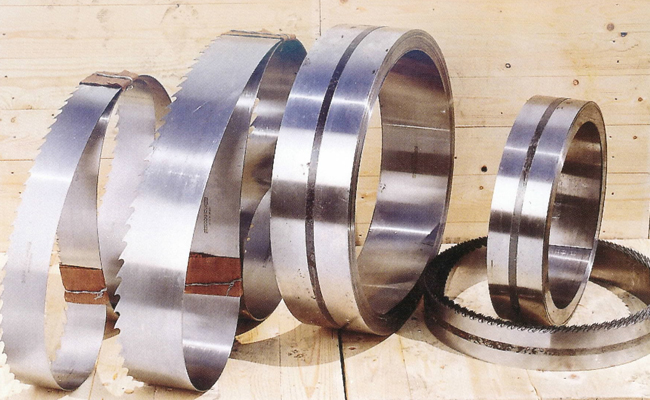

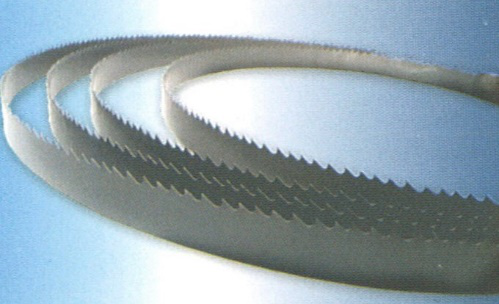

LBSB is the pioneer in the region offering completely made up ready to use bandsaw blades. Our nickel alloy steel bandsaw blades are manufactured using latest Flash Butt welding machines

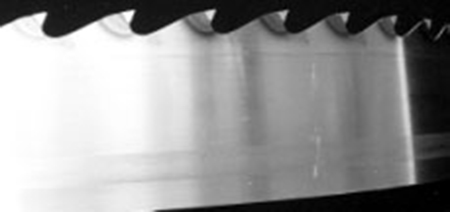

Automatic Stellite tipping machine is used for tipping high precision saw kerf to save on expensive Wood.

We offer 80mm, 100mm, 4", 4.1/2", 5", 6", 7" & 8" width bandsaw blades with thickness of 19G, 18G, 17G.

Our Steel adheres to strict tolerances for uniformity of thickness & straightness, consistent hardness, and all EU quality standards. This steel delivers an easily swaged tooth that is both tough and resistant to wear.

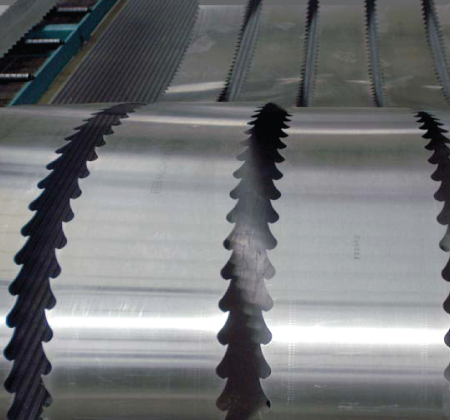

A variety of tooth shapes are offered to suit almost every resaw application and cam profile.

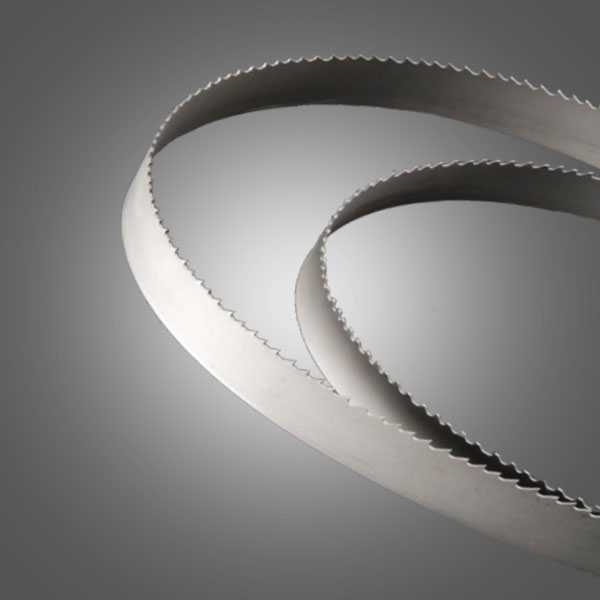

Skarpaz butt welds are tempered to withstand rugged use and are finished to a high standard. Using our proprietary process we are able to weld some of the thinnest wide bands.

Bands can be supplied as single cut, double cut, or with a Sliver tooth back. Toothed coils can be supplied on request.

With a combined 100+ years experience of wide band tensioning and leveling on hand, you can be assured that bands track and run correctly every time out of the box.

Hardened and tempered HRc44-45

Straightness: Max. deviation

0.25mm/1000mm (0.01"/39.4") or

Max. deviation

0.80mm/3000mm (0.03"/118")

Our stellite tipping process has been recognized as a superior value both in terms of cost effectiveness and finished tip quality and accuracy. Special thin kerfstellite bands and frame saw blades are available.

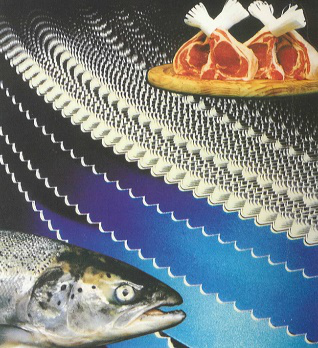

Other than timber cutting, LBSB offers full range of Narrow Bandsaw ( ¼" to 2" width) thickness 0.45, 0.60, 0.70 & 0.80 mm, used for the following applications:

Our Quality bandsaw steel is imported from leading English & Japanese steel mills. Customers have a choice of variety in quality depending on usage and budget.

BI METAL Bandsaw

BI METAL Bandsaw

We are Exclusive Distributor for Bichamp,

Our Supplier of high quality bi-metal bandsaw made with sophisticated manufacturing facilities combined with highly skilled, experienced manufacturing team.

Bichamp offers various combination of teeth hard material and backing material to perform simple cutting task to difficult, demanding cutting operation.

Wear resistant PMP tooth tips combine with reliable 4%Cr backing material make this general- purpose blade suitable for cutting various commonly used materials.

Applications:

Features:

PM Tooth tips combined with reliable 4%Cr backing material make this general-purpose blade the all-round blade for cutting more commonly used materials

Applications:

Features:

&

&

Engineered for sawing medium to large work pieces with high precision & clean cut surface.

High-Low tooth design is engineered to reduce cutting force, resulting in smooth and efficient cutting.

Applications:

Features

&

&

Carbide tipped bandsaw blade with a Multi-Chip geometry, that is designed for cutting difficult to cut materials providing excellent cutting performance, toughness and wear resistance.

Applications:

Features: